Simplify logistics with used collapsible containers for better operations

Ingenious Solutions: Uncovering the Convenience of Bulk Containers in Various Industries

Bulk containers have actually arised as a crucial technology throughout numerous industries. Their style enhances storage space and transport effectiveness, accommodating diverse requirements while promoting sustainability. Services in agriculture, manufacturing, and logistics report substantial renovations in operational processes. Nevertheless, real extent of their impact might not yet be fully recognized. Checking out the various applications and advantages of bulk containers might expose understandings that improve sector requirements. What lies ahead for this progressing remedy?

Enhancing Agricultural Efficiency With Bulk Containers

How can mass containers transform farming techniques? In the domain of agriculture, bulk containers act as a pivotal advancement, boosting effectiveness and sustainability. They enable farmers to keep and transfer big amounts of fertilizers, seeds, and grains, decreasing the need for several smaller sized packages that usually contribute to lose. By utilizing mass containers, farming operations can maximize their supply chains, lowering managing prices and time. These containers are made for very easy loading and discharging, allowing for speedy shifts between various stages of farming procedures.

Bulk containers advertise better stock management, making certain that producers have sufficient products on hand without unwanted. This effectiveness converts to minimized labor costs and enhanced performance. In an industry frequently challenged by fluctuating need and seasonal variants, the integrity and scalability provided by bulk containers provide a significant benefit, equipping farmers to focus on quality and yield.

Enhancing Manufacturing Processes Via Mass Solutions

Bulk services play an important duty in streamlining manufacturing processes by facilitating efficient material handling and giving affordable storage space choices. These containers aid keep an orderly production atmosphere, inevitably improving operations and efficiency. As sectors progressively embrace bulk options, they are likely to experience considerable improvements in functional performance.

Effective Material Handling

Effective product handling is important for enhancing production processes, as it directly affects performance and cost-effectiveness. Utilizing mass containers can significantly simplify procedures by simplifying the movement and storage space of products. Their layout permits easy loading and discharging, reducing the moment employees spend dealing with private products. This performance not just reduces labor costs however likewise enhances operations, enabling manufacturers to react swiftly to require fluctuations. On top of that, mass containers promote far better organization within centers, facilitating fast access to materials and reducing downtime. By executing these versatile solutions, makers can boost general functional efficiency, ensuring that production lines run smoothly and successfully while decreasing waste and source expense. Consequently, bulk containers play an important function in enhancing material handling methods.

Cost-Effective Storage Space Solutions

As makers seek to optimize their procedures, economical storage space remedies become significantly essential. Bulk containers give a sensible methods of storing huge amounts of materials, decreasing the requirement for numerous smaller storage units. This loan consolidation brings about lower stock costs, as mass containers usually need much less handling and cause decreased labor expenditures. Furthermore, their standardized dimensions assist in effective piling and storage space, making best use of warehouse room. By making use of mass containers, producers can lessen waste and enhance the total company of their facilities. These containers are also designed for longevity, which can minimize substitute prices with time. In general, integrating bulk containers into storage approaches enables producers to streamline operations while keeping success and efficiency in their supply chains.

Enhanced Manufacturing Process

Using bulk containers considerably enhances manufacturing process by streamlining the management of materials throughout the manufacturing process. These containers help with effective storage space and transportation, minimizing the moment spent on handling materials. Therefore, suppliers can accomplish quicker turn-around times and minimize delays in manufacturing. Mass containers also promote better organization, enabling groups to easily access raw materials when required, which additionally enhances operations. Furthermore, the standard size and form of these containers allow maximized use of storage facility space, contributing to overall performance. By incorporating mass services right into their procedures, firms can boost inventory control and minimize waste, eventually resulting in increased productivity and a much more active production atmosphere.

Reinventing Food Service Logistics

The food service sector is undergoing significant improvement through the fostering of bulk containers, improving storage space capabilities and enhancing area use. Reliable storage space remedies allow organizations to manage inventory better, while structured transport processes lower costs and boost delivery times. Consequently, these technologies are reshaping logistics and driving better effectiveness across the sector.

Effective Storage Solutions

Ingenious storage space services are transforming food solution logistics by boosting effectiveness and optimizing room usage. Mass containers, designed for maximum capability, allow food company to minimize lost area while keeping very easy accessibility to products. These containers can be stacked and arranged according to inventory requirements, enhancing the storage process. Furthermore, their sturdiness assurances that food products stay protected and safe, lowering perishing and losses. With attributes such as modular styles and compatibility with numerous shelving systems, these containers can adapt to varied kitchen area layouts. By utilizing reliable storage space services, food service operations not just improve process yet also boost overall performance, assuring that resources are used successfully to fulfill customer demands.

Streamlined Transport Processes

While several factors add to the performance of food solution get more info logistics, streamlined transport processes play an important duty in maximizing supply chain operations. The adoption of mass containers substantially enhances the activity of products, permitting quicker loading and dumping at distribution centers. Their standard dimensions facilitate effective piling and storage, lessening lost room during transportation. Additionally, bulk containers decrease the need for excessive product packaging, resulting in reduce costs and lowered environmental influence. By making certain that items are securely moved, they alleviate damages and spoilage, which is crucial in the subject to spoiling food industry. Generally, the integration of mass containers into transport strategies not only enhances operational effectiveness yet likewise supports lasting techniques within the food service industry.

The Function of Mass Containers in Drug Supply Chains

In the pharmaceutical industry, bulk containers play an essential role in guaranteeing the safe and effective transport of raw products and finished products. These containers are especially made to fulfill rigorous regulative needs, giving optimal defense against contamination and deterioration throughout transit. Their robust building and construction enables the safe transport of sensitive products, such as active pharmaceutical ingredients (APIs) and intricate formulations, while decreasing the threat of damages.

Bulk containers promote streamlined handling and storage space operations within storehouses and production facilities. Their standardized sizes make it possible for compatibility with automated systems, improving productivity and decreasing labor expenses. By using bulk containers, pharmaceutical firms can accomplish substantial price financial savings through bulk investing in and lowered product packaging waste.

Promoting Sustainability in Packaging Practices

The pharmaceutical sector's boosting reliance on mass containers has prompted a more comprehensive evaluation of sustainability in product packaging methods throughout various fields. As firms look for to decrease their environmental influence, innovative strategies to packaging have actually acquired grip. Mass containers, created for reuse and recycling, present a sensible option. Their longevity extends product lifecycles, minimizing the demand for single-use packaging.

The shift towards environmentally friendly coverings and eco-friendly products has come to be important in the layout of these containers. This modification not just addresses waste decrease but additionally aligns with customer need for lasting items.

Industries such as food and cosmetics are embracing comparable methods, acknowledging that sustainable product packaging can improve brand online reputation. Joint efforts between producers and distributors better advertise sustainability, urging the growth of closed-loop systems - used collapsible bulk containers. Ultimately, accepting sustainable product packaging techniques is important for fostering a round economic situation and minimizing the environmental impact throughout diverse markets

Cost-Effective Transport Solutions With Mass Containers

In addition, bulk containers improve dealing with processes, causing reduced labor expenses and minimizing the risk of damages throughout transportation. Industries such as agriculture, chemicals, and pharmaceuticals benefit from the resilience and effectiveness of these containers, which can hold up against extreme conditions while guaranteeing the stability of their contents

Furthermore, the recyclable nature of bulk containers contributes to long-term financial savings, as firms can depend on fewer, extra sturdy devices as opposed to regularly replacing single-use product packaging. By doing this, bulk containers not just enhance performance but additionally sustain general price management in supply chain procedures.

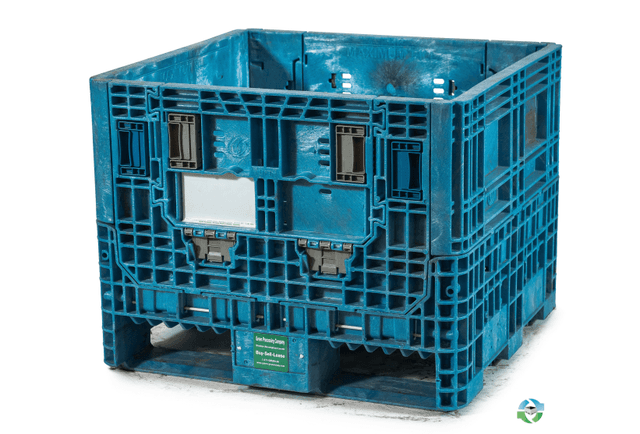

Customization and Versatility in Mass Container Style

While many bulk containers are developed for typical applications, their customization and flexibility have actually become important attributes for industries with one-of-a-kind demands. Suppliers now provide a series of alternatives, enabling customers to customize containers to particular measurements, materials, and performances. This flexibility allows services to enhance storage and transport procedures, making sure compatibility with various taking care of systems.

For example, the food and pharmaceutical industries commonly require containers that meet strict hygiene and safety criteria. Personalized layouts may include attributes such as tamper-proof seals, easy-to-clean surface areas, and specialized air flow systems. In the agricultural market, bulk containers can be tailored to help with the transport of diverse commodities, from grains to liquids, improving operational effectiveness.

Inevitably, the capacity to tailor mass containers not just increases efficiency but also supports sustainability efforts by lessening waste and making best use of source utilization across numerous industries. This adaptability placements bulk containers as functional remedies in today's dynamic market.

Frequently Asked Inquiries

What Materials Are Mass Containers Generally Made From?

Mass containers are usually made from materials such as high-density polyethylene (HDPE), steel, polypropylene, or aluminum. These products provide longevity, resistance to chemicals, and the capacity to securely store and transport different products throughout markets.

Exactly How Are Mass Containers Cleaned In Between Uses?

Bulk containers are commonly cleaned up using high-pressure washing, steam cleaning, or chemical sanitization approaches (used plastic containers). The cleaning process warranties that residues are gotten rid of, avoiding contamination and maintaining the quality of components for succeeding usages

Can Bulk Containers Be Recycled Several Times?

Yes, bulk containers can be reused numerous times. Their robust layout permits for duplicated use throughout various applications, provided they are effectively cleaned and preserved after each usage to guarantee security and hygiene requirements.

What Are the Weight Purviews for Bulk Containers?

Weight limitations for mass containers normally range from 1,000 to 3,000 pounds, relying on the material and style. Specifications may vary by producer, so it is crucial to seek advice from standards for certain container types.

Exist Standard Sizes for Bulk Containers?

Yes, there are common sizes for mass containers, generally varying from 20 to 40 cubic feet. These dimensions promote efficient storage space and transport throughout numerous sectors, guaranteeing compatibility with devices and maximizing space application.

Making use of bulk containers can noticeably enhance procedures by streamlining the activity and storage space of products. In addition, mass containers promote far better organization within centers, helping with quick access to materials and decreasing downtime. Mass containers supply a functional ways of keeping large amounts of materials, reducing the requirement for multiple smaller sized storage space devices. The food solution market is going through considerable change via the fostering of bulk containers, enhancing storage space abilities and enhancing area usage. Bulk containers assist in structured handling and storage space procedures within warehouses and production facilities.